Oct. 26, 2021 | Engineering |

Picture it: you've been training for years to become an astronaut and contribute to the world’s knowledge and advancement of outer space. The big day has finally come, and you take that first victorious step onto the launchpad where the rocket awaits. Your main mission is clear: land at the International Space Station and work with the team to make discoveries, conduct experiments and participate in the upkeep of the station itself. However, your unspoken mission is to survive in outer space, miles away from home with limited resources. Water taken onto the station is cleaned and prepared for reuse by the Water Processing Assembly, providing a limited yet constant supply for the astronauts. The current system uses thermal energy to purify the water, but the WPA itself develops bacteria and must be cleaned routinely. What if a more efficient method of purification could be applied to the system? Here at Harding University, the engineering and physics department is hard at work to answer that question.

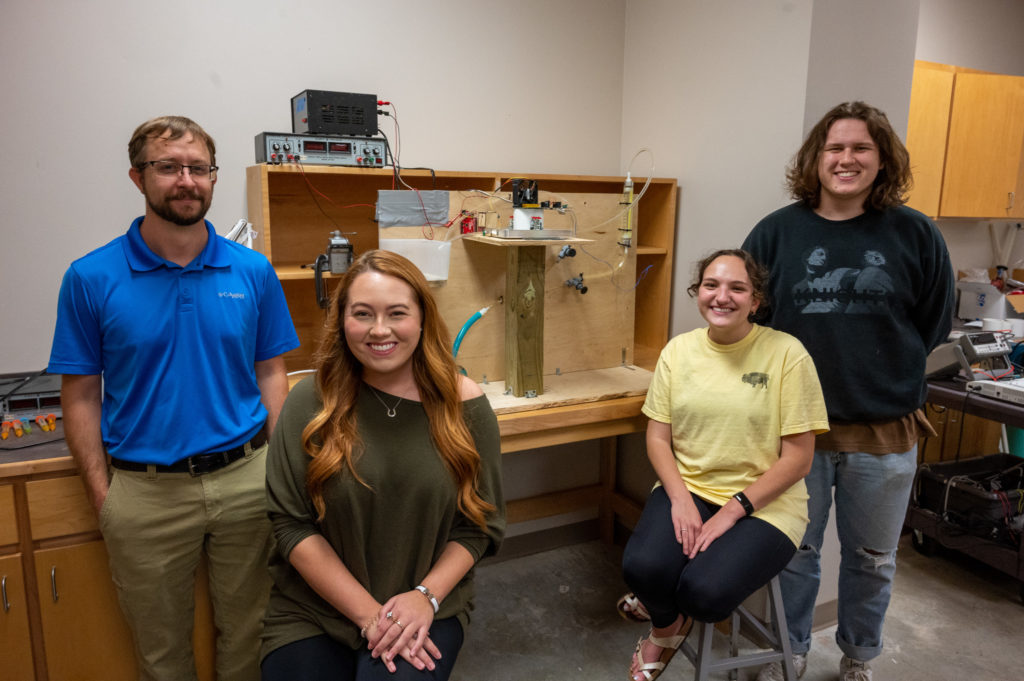

Harding faculty, in partnership with the University of Arkansas at Little Rock, and funds from the Arkansas Space Grant Consortium (NASA Training Grant 80NSSC20M0106) make the water purification project possible. Dr. Dennis Province, former Harding professor, and Dr. Cindy White, associate professor and chair of the chemistry department at Harding, partnered with scientists at UALR to develop a method of purifying water using UV light technology instead of the more traditional method using thermal energy. The next step was to integrate it into a physical system. For the last year, Dr. Jeff Massey, assistant professor of engineering and physics at Harding, has been leading students in designing a functioning water purification system to apply the UV light technology.

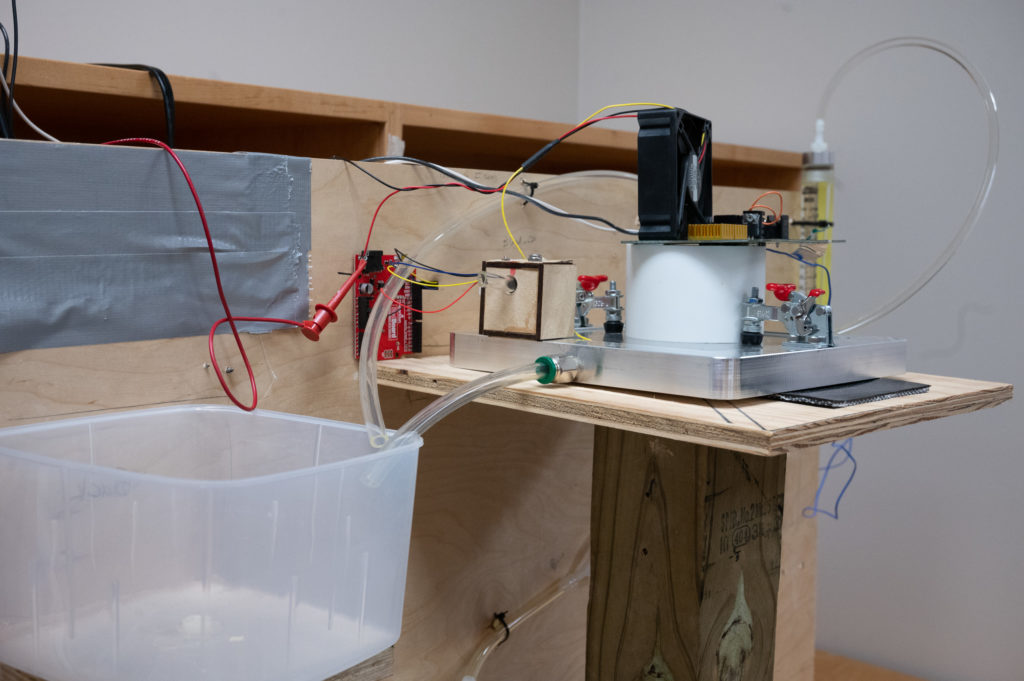

Although Harding’s project aims to produce a system that functions similarly to the current WPA used by the ISS, there are a few significant differences between the two. The current Water Processing Assembly uses thermal energy to purify water, but Harding’s project uses ultraviolet light —delivered by LEDs — to clean the water, which is theorized to be more efficient and easier to control.

Since UV light is more efficient in theory, one might wonder why it hasn’t already been developed for use in the WPA. Dr. Massey explains: “God [has] been doing this since He created the earth, so the principle has been there forever….Trying to harness it and control it in a way that we can use it for a chemical or physical system — that’s a newer approach than the thermal.”

The water purification project aims to create a functioning system that can be used by the International Space Station; however, Dr. Massey explains that the overarching goal is to provide Harding students the opportunity to participate in a hands-on research and application process. In fact, the continuation of the project depends on whether there are students interested in participating. This year, senior mechanical engineering major Brooke Ashworth, sophomore biomedical engineering major Libby Selvidge and junior computer engineering, computer science and math major Joshua Milnes are three students taking on the challenge.

How does this project help you in reaching your career goals?

Brooke : “It’s been a lot of trial-and-error on my part. Last fall I helped with the CAD [computer aided design] modeling. This spring we decided to look more at the chemistry side [of the project]. My dream job is to be an engineer for a makeup company, so taking a little bit of time to look at the chemistry aspect of things gave me some education and background understanding of [chemical engineering]. You have to learn how to think for yourself. That is one thing about engineering that I really learned the hard way. My sophomore year, I used to always try to memorize how to do all these math problems and formulas. You slowly realize that it doesn’t work that way when it comes to engineering. In the real world, you need to have those skills, but at the end of the day, you have to know how to apply that. You can’t just memorize how to do it because it’s different in every situation. This [project] definitely gave me that experience of having to figure it out without someone telling me how to do it.”

Libby : “It’s good application. In high school, I was pretty lucky to be able to experience what an engineering process is like because I was on the robotics team. I can’t imagine what it would be like not having that because, so far in my classes, you don’t really have a lot of stuff like this yet — where you’re doing all of the steps of an engineering design process. It was really cool already having that with the robotics team [and] being able to do it outside of my classes. It’s useful because you are familiar with what your job will look like. You can learn all the information, but the application practice of it is different from just learning it from a book.”

Joshua : “This project will put me one step ahead of others in my field. Having this extra experience will help me get a good internship this upcoming summer and, hopefully, put me at the front of the pack when looking for jobs after graduation. I think this project will be helpful to my teamwork skills, communication and time management. I also believe this project will provide me an extra foundation for how project-based engineering works in the real world, and I am very excited to apply this to my future careers.”

With support from students, faculty and funds, Harding’s water purification project is on the road to making a difference in the Water Processing Assembly of the International Space Station itself, aiding astronauts in the hard work they do for the world.